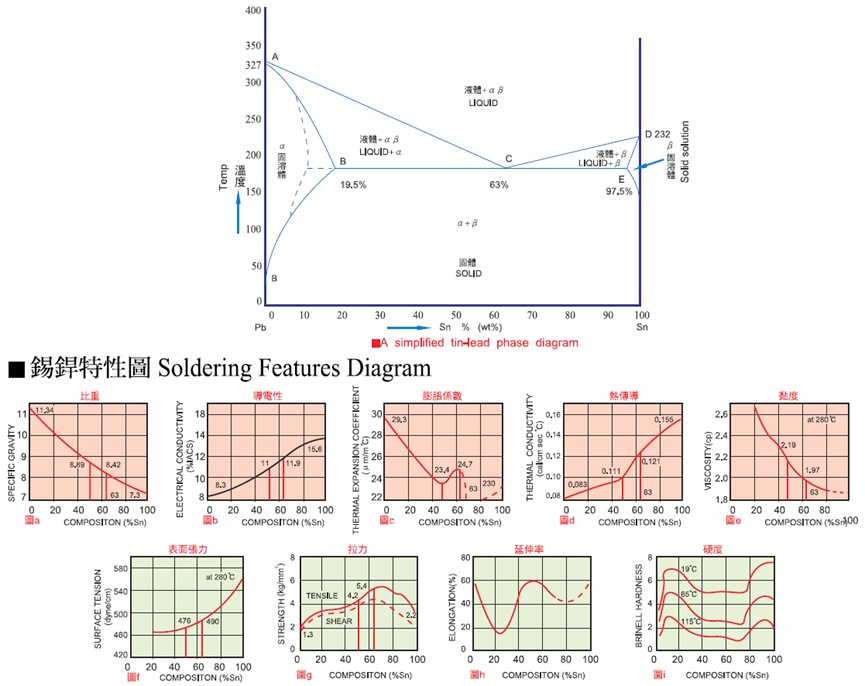

■ Sn/Pb焊錫狀態圖及適用溫度

如下圖所示,錫鉛合金自Sn 19.5%起至97.5% ,有均一不變的固相線即BCE線(183.3°C) 。ABC及CDE皆為半熔融狀域,而ACD曲線則表示液相線。固相線液相線兩線會合點C點是為共晶點。其時,錫鉛含量為63/67 。換言之,當焊錫之錫為錫63%鉛37% 時,可自液體狀直接變為固體狀或自固體狀直接轉變液狀,而不經半熔融狀。其他成份之焊錫,則均在183.3°C至ACD液相線中間形成半融狀。液相線熔點並非適當的焊錫溫度,通常之適用溫度約高於該焊錫之液相線溫度55°〜85°C。

■ Application and soldermg

As shown in figure below, there is a solidus temperature line ftom Sn 19.5% to 97.5%—BCE(183.3°C). ABC and CDE aie plastic state. Curve ACD is the liquidus temperature line. Point C is the eutectic point where the solidus temperature line and the liquidus temperature line meet and the tin-lead contents will be 63-37. When the alloy contains 63% of tin and 37% of lead, it may change directly from liquid to solid or from solid to liquid without going plastic state between 183°C to curve ACD. The melting point on the liquid temp. Line is not the right temperature from soldering. Usually, The applicable sol应ring temperature is 55*C 〜85°C higher.

既然大家都希望於最低溫度下完成焊錫工作,那就得利用熔點最低之焊錫,錫63%鉛37%之共晶點焊錫可符合此項要求,其理由有如下三點:

(1)因其不經過半熔融狀態而迅速的固化或液化,因 此可以最快速完成焊錫工作。

(2)能在較低溫度下起始焊接作用,乃錫鉛合金中焊 接性能最佳之一種。

(3)溶液之潛鑽力強,可札根般地滲透金属上之極微細隙。

■ The Eutectic Solder

Since we want to solder at the lowest possible temperature, we want lhe solder with the lowest possible melting point. This would, of course, be the eutectic alloy of tin and lead which is 63% Tin and 37% Lead. There are Ihree reasons for that:

(1)Soldering can be fast completed, owing to the direct liquidation or solidation without going through the plastic state.

(2)Welding at low temperature, lhe best choice for tin-lead alloy.

(3)High penetrating ability to reach any small interstices of the metal.